News

Please check various news

and information

through

SamWoo's notice.

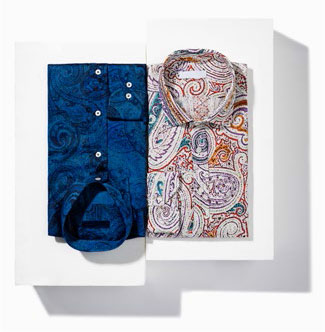

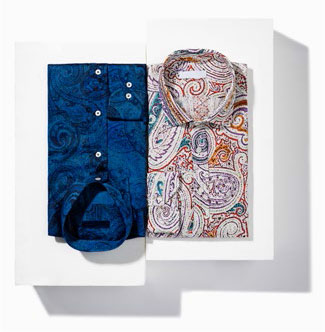

You can find a solution from dyeing, ombre,

digital printing from Samwoo DTP!

Please check various news

and information

through

SamWoo's notice.

[Fashion Journal & Textile Life: Ansan = Reporter Park Sang-ji] The digital printing specialist Samwoo DTP (CEO Nam Yoon-ho) changed the company name (formerly Sangwoo Digital Printing Co., Ltd.) and established a new step in the leap forward.

Samwoo DTP (Samwoo DTP) changed its name from the existing Samwoo Digital Printing, followed by the parent company Samwoo Silk (CEO Nam Woo-Hyun) head office (in Choji-dong / Banwol Industrial Complex, Ansan-si, Gyeonggi-do) with a site of 600 pyeong and floor space of 500 pyeong (office and DTP factory Separation) new factory (14, Byeolmang-ro 677beon-gil, Danwon-gu, Ansan-si, Gyeonggi-do / Changseong coating site) was moved and expanded.

Samwoo DTP, which started operation in earnest from the beginning of October after expanding the company in 8 years since the company's establishment in 2009, is water repellent / antibacterial, including digital printing of various fabrics such as cotton, silk, poly, poly, cotton, nylon, cotton, and blends. High-sensitivity and multi-functional technology such as / deodorization / moisture absorption We have built a foundation to focus on material processing and silk finished product development.

SAMWOO DTP was established in 1987 as a leader in domestic silk dyeing and silk dyeing, and is a subsidiary of SAMWOO Silk. It is making the second leap forward with SAMWOO DIP by producing DTP finished products such as handkerchief and scarf.

Samwoo DTP's new factory is leading the development of high-functionality, high-quality technologies such as single-sided, double-sided processing, and special post-processing, while investing about 600 million won to invest in the latest facilities, including the introduction of the Italian Mona Lisa (acquired by Epson) DTP machine. Reactive equipment, etc. were reinforced, and various and vivid colors were realized, and output speed was improved.

In the second half of last year, in collaboration with Dr. Shim Jae-won, a senior researcher at the Korea Institute of Industrial Technology, it was the first in Korea to successfully process single-sided water repellent / back-side moisture absorption. It was developed using a processing machine.

Since the front and back heterogeneous processing is a coating method, it maintains the original material texture and breathability, and water repellency is possible at the same time.

In addition, when converting to a coating method that is applied to the conventional method of squeezing and drying from padding during processing, water consumption is greatly reduced. Up to 70% more energy savings and more than 50% defective rate can be minimized compared to the existing mangle-based drying method.

Above all, the coating method can be processed only on the surface of the fabric compared to the existing mangle method, so it can process more than 50 times of washing durability depending on the fabric by processing high concentration chemicals by unit weight.

In particular, this processed product is highly environmentally friendly, such as water-repellent, oil-repellent, antifouling, deodorizing on the outside, and highly functional, such as moisture absorption, antibacterial, hangover, flame retardant on the inside. It is expected to contribute.