Dyeing

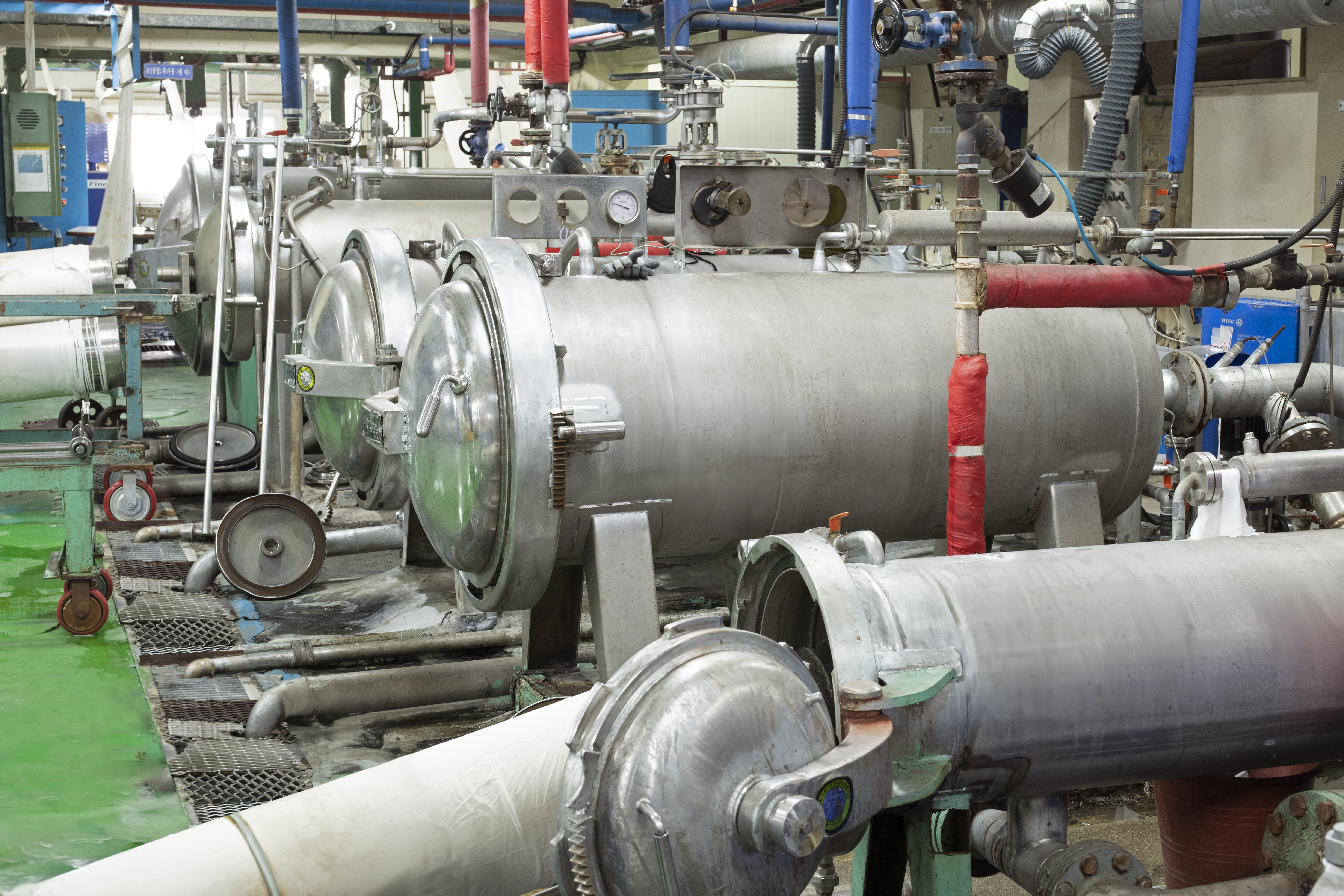

It is a method of winding the cloth in a cylindrical shape on a perforated cylindrical beam, fixing it on a dyeing machine, and circulating the dye inside and outside to dye it. Less wrinkles, elasticity and texture can be obtained, suitable for natural silk dyeing.

Strong Point

In case of dyeing, if customer designates certain color, we match with the recipe of color through L/dip test in our lab and we get the confirmation with the customer after dyeing sample. After that, for the main dyeing, the fabric is wound on a beam, and then put into a dyeing machine. After the dyeing process, our tenter can dry and touch the fabric as customer’s desire.

Work Process

Receiving -> L/dip Test -> Dyeing -> Tenter -> Fabirc inspection -> Packaging

Receiving01

Puttingon fabric in our factory

LAP TEST02

After selecting the color, we check the sample with the actual feeling and we proceed with main dyeing work.

Dyeing03

The cloth is wound around the perforated cylindrical beam in a light cloth, and it is fixed to a dyeing machine, and the dye is circulated outwards for dyeing.

Tenter04

This is the process of physically straightening the fabric by fixing both salvages of the fabric. By the tenter processing, it can be increased to the desired width, and at the same time, it can prevent wrinkles and adjust the fabric's all directions correctly.

Inspection05

Process to check fabric and print quality before cargo is ready

Packaging05

Deliver the package whatever cusomer wants(ex : courier or others)